|

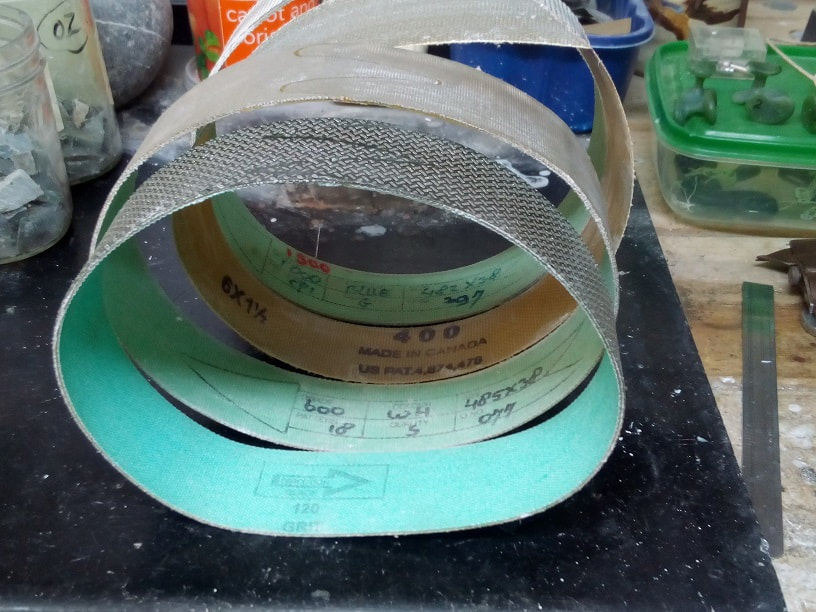

The humble expandable rubber drum and smaller, slotted expanding drums are important tools for carvers. The smaller sizes give us the opportunity to grind surfaces which are depressed or concave (curved inwards along one or two axes) with accuracy where otherwise a large dental burr might be needed. I use 6, 12 & 25 mm diameter models on a regular basis. The large drums allow us to grind and polish surfaces which may be curved along one axis (a ridge) or two axes (convex) and I use a 150 mm diameter x 38 mm wide drum. The tools themselves are usually mounted on a mandrel which fits into a chuck. Make sure you mount the drum on the mandrel the correct way around so it is thrown open by the direction of rotation, and not closed. The point of the expansion is so a belt can easily be slid onto the drum when it is at rest and, when rotated, the diameter of the drum expands and locks the belt in place through centrifugal force. The smallest drums expand due to tightening either a screw or nut located at one end. I’ll discuss the pneumatic sanding drums in a later blog as they are quite a different animal. Drums begin at 6 mm diameter x 15 mm long (the small belts which fit them are sometimes called spiral bands) all the way up to 200 mm diameter x 75 mm wide. Belts can be covered in grits ranging from 60 (very coarse) – 50,000 (polishing) in either silicon carbide or diamond. I prefer the latter, and they are not expensive for the work they do. I have a number of well-used (they become less aggressive as they wear) and newer, “sharper” ones in the following sizes: 60, 120, 240, 400, 600 & 1500. I hardly use the last one as I prefer other methods to polish my work. Flexible belts can have the diamonds attached by either electroplating or resin bonding. One method is basically as good as the other. Some belts have a regular pattern of distinct “dots” over the surface of the belt whilst others have tighter coverage of the abrasive. The coarser dots can fly off in use, so wear eye protection at all times. I picked up a couple of beautiful coarse belts from a UK company recently which have a tight overlapping pattern of abrasive – they are very aggressive (the belt on the left in Picture 4 above) and good for cutting back on the rough! A good supplier for the larger drums is Rayspan, and AbTec (UK) is good for the small slotted expanding drums. Crystalite/Abrasive Technology (USA) make a good range of belts and spiral bands, but there are many more excellent producers out there. Important points to remember:

I hope the notes above de-mystify these useful tools for you?

4 Comments

Anthony Rewiri Tarapata

8/6/2020 04:29:51 am

Thanks so much for the handy tips, Nigel Brown, these are the need to know tips all Jade and Pounamu should be aware of when setting up their workstation

Reply

8/6/2020 04:46:46 am

Thank you Anthony - your comment makes it all worthwhile. Happy carving!

Reply

Rāwiri

28/1/2024 02:27:23 am

Kia ora Nigel! Thank you for all the mahi, time and matauranga you've put into this site! I'm an amateur carver and have just spend the last two days going through all your posts!

Reply

29/1/2024 12:56:33 am

Hi, thanks for your kind comments. One company in NZ which I've purchased useful materials from in the past (that's as far as my endorsement can go though) is CDK Stone. Their website is <cdkstone.co.nz>. They sell expandable rubber drums (make sure you put it on the mandrel the right way around so it expands and locks the flexible belt as it rotates!). You will also need a mandrel, and then a selection of diamond belts. I've been using the 150 x 63mm size, though there is a larger one, which means material costs increase accordingly. Good luck!!

Reply

Leave a Reply. |

AuthorOn this page I intend to add monthly updates on aspects of jade carving. I also plan to invite more experienced carvers to offer a "master-class" on a particular subject of their choice. With this I hope to enthuse both the novice and the expert in this ancient and beautiful art-form/craft. And comments are welcome! Archives

March 2024

Categories |

RSS Feed

RSS Feed