|

The set-up of the equipment is important because I am playing with fast-moving equipment and large chunks of stone. I oil & grease the bearings and use the fastest speed possible – around 2500 rpm on my equipment. Tighten every nut & bolt. Check the cooling water system is ready. The slabbing guide sits on top of my larger saw blade rest.

As the picture above shows, the slabbing guide is adjustable for slab thickness. Make sure the plate is square and perpendicular to the bed of the slabbing guide. It really helps if the rock you are cutting has at least one flat face on it to make handling easier. Turn on the cooling water and check it is flowing onto both sides of the blade – I use a torch to look down the rest slot. Put on your eye and ear protection and waterproofs against the inevitable spray that is going to be thrown out at you. Power-up! Check everything is running smoothly. Arrange the stone so a flat surface is pressed against the side of the guide. Ease it forward and begin the cut. Well, it is a grind it really as I’ve said before. Keep your eyes open for things to go wrong! Don’t let the rock ride-up on the blade as you push it in – keep sideways pressure on the rock against the guide, downwards to keep it on the bed of the slabbing guide and push it forwards. This can be done in two ways: 1) with a steady pressure on the blade, balancing the pressure to the speed of the motor – you can sense the speed quite easily even with ear protection on, or 2) by pressing a little harder and then holding the rock at that point until the speed of the blade builds up again. The first way is probably better for both the life of the motor and blade. As I cut deeper into the stone the motor seemed under-powered for some reason. I nursed it along for a while before noticing the fan-belt was unduly loose and flapping around. I was sure I’d adjusted the tension before starting up! I gently pulled the stone off the blade, stopped the motor and adjusted the belt tension. I started the motor up again and went back to the cut, and again, the power gradually dropped. I completed half the cut and thought I should turn the rock over to start from the other end or I wasn’t going to be able to cut the whole slab. Very strange!

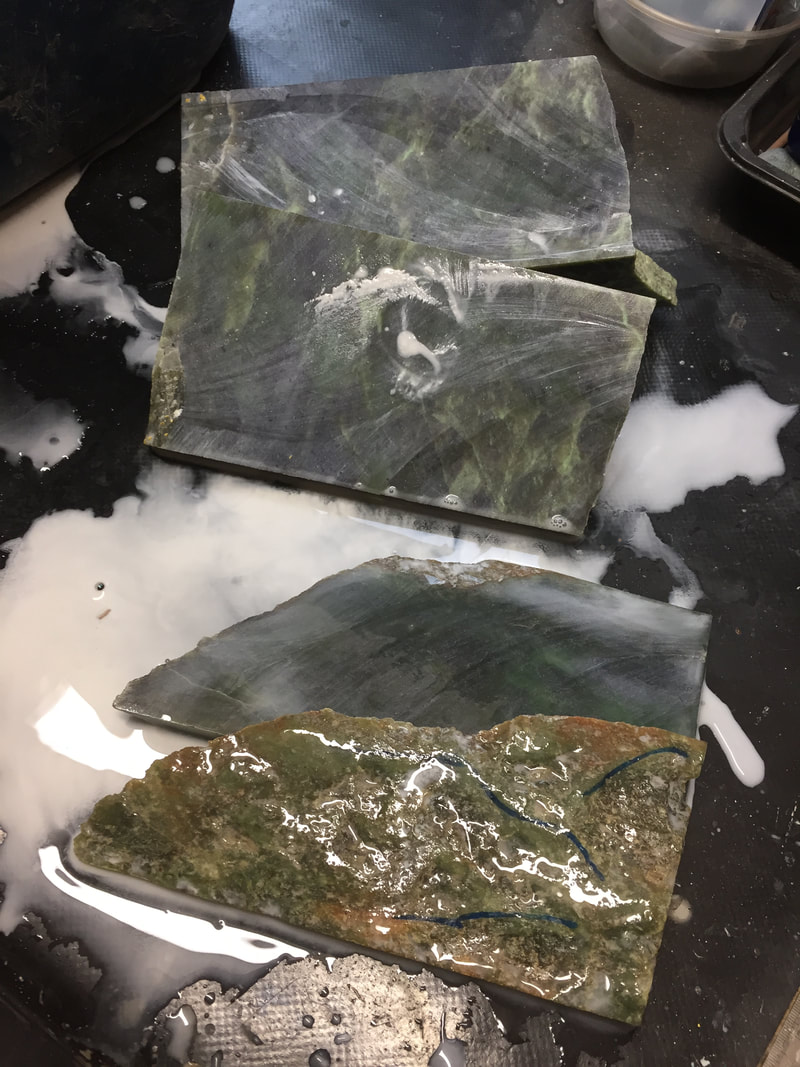

The cutting was still quite tentative – I needed to keep up the rpm, and it had no power. I noticed the belt was again loose and the tension adjustment wheel was gradually turning with the vibration – that hasn’t happened before! I wedged a block of wood underneath it to prevent movement. This gave me a lot more power, and I completed the rest of the cut. The last few mm of rock broke through as they always do. Don’t grind off these jagged little pieces at your peril – they can be a real nuisance and you’ll cut and scratch yourself every time you pick up that piece of rock! But you also need to keep an eye on how full the bucket is – and stop and empty it if necessary. If you do need to stop the motor, carefully remove the stone from the blade whilst it is still running – it is easy to buckle the blade if you remove the stone when it is not rotating. The second piece of rock that I wanted to cut a slab off was slightly higher than the blade so after I’d completed the first cut, I again turned the rock upside-down and cut through the remainder. It went well except for slurry overflowing the box sump for some reason. It was probably full with cuttings and backing up. I just shifted a second bucket with my foot into a strategic place to catch the stream of muddy drips. As I say, be aware of what is happening! As the slabs were quite thick and some of the cuts for my design needed quite a bit of clearance, I also trimmed the pieces before shutting things down. By cutting out “V’s”, cutting off corners and cutting into the stone, I saved myself a lot of rock and time in the forming stage.

That done, I disassembled and cleaned the equipment, dried up the bench and was happy to look at the results. Mission accomplished!

0 Comments

Leave a Reply. |

AuthorOn this page I intend to add monthly updates on aspects of jade carving. I also plan to invite more experienced carvers to offer a "master-class" on a particular subject of their choice. With this I hope to enthuse both the novice and the expert in this ancient and beautiful art-form/craft. And comments are welcome! Archives

March 2024

Categories |

RSS Feed

RSS Feed